The process is generally performed at room temperature but in some special cases the sheets can be pre heated to improve the material ductility and thereby avoid the formation of cracks during the process.

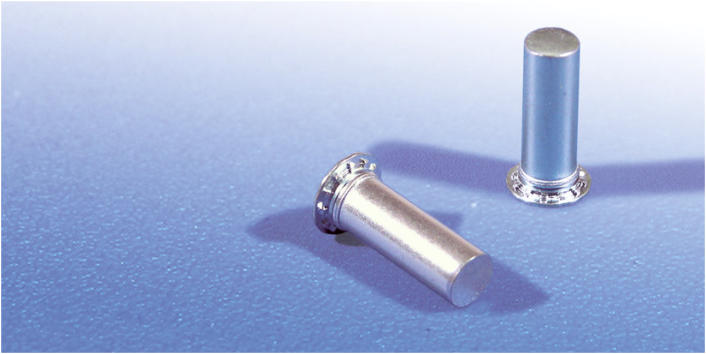

Clinch on pins for sheet metal.

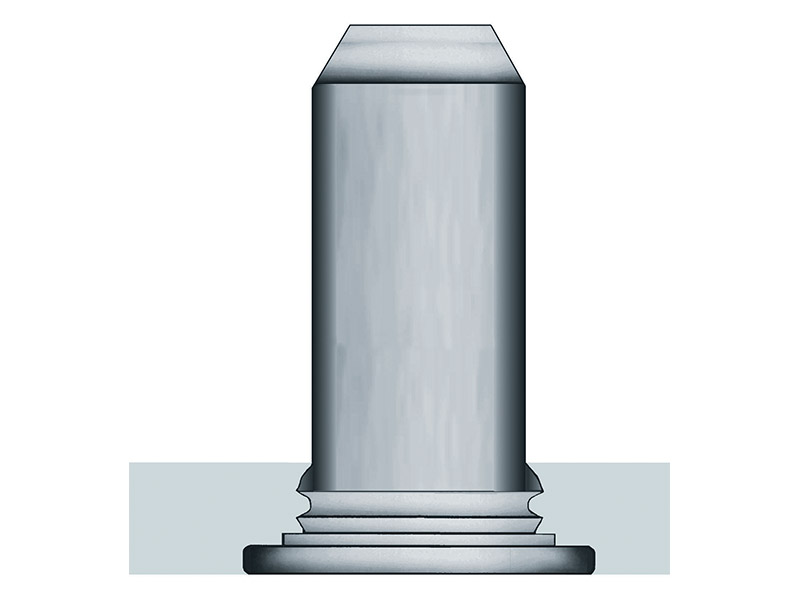

Self clinch flush head pin.

Sheet metal clinching styles clinching point shapes tox pressotechnik.

Please select a size below for further information and 3d model.

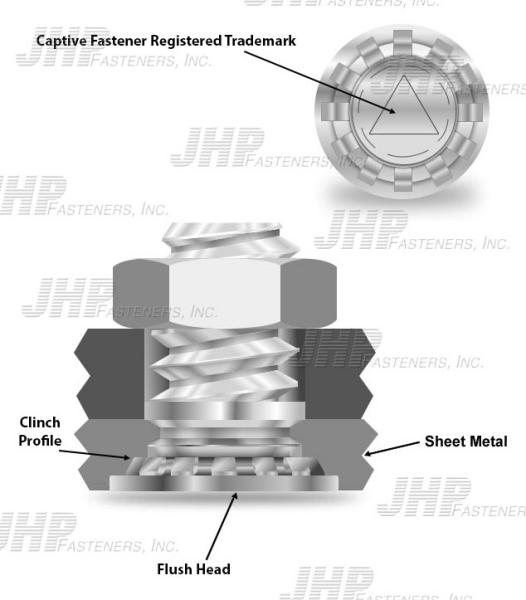

Clinch joining is also known as press joining or clinching.

They can be installed into a variety of sheet materials up to hrb 92 hb 195 in hardness and they offer excellent corrosion resistance.

Simply pressed into a properly sized mounting hole these micro pins clinch permanently into place.

One type of self clinching pin is often used as a guide pin when aligning other components for assembly.

These captive fasteners operate in the same way as the self clinching studs but provide a permanently installed male pin of a certain diameter.

Installation and tooling.

Hairpin clip assortments clip these pins onto grooved shafts and clevis pins to keep components in place.

Clinching is characterized by a series of advantages over competitive technologies.

The tox clinch procedure is a proven substitute for welding screwing riveting.

Pem type mpp self clinching micropem pins are ideal for today s compact electronic assemblies.

Catalogue fasteners for sheet metal hank self clinch fasteners flush head pins.

A punch is pressed through both layers of sheet metal into a die and in such a way that the sheets become locked together.

Clinching or press joining is a bulk sheet metal forming process aimed at joining thin metal sheet without additional components using special tools to plastically form an interlock between two or more sheets.

The thfe is recommended for use in steel or aluminum sheets hrb rockwell b scale 85 or less and hb hardness brinell 165 or less.

For further information visit our website http.

It is one way to quickly and cost effectively join sheet metal without the use of fasteners welding or adhesives.

The enlarged head diameter reduces stress on the panel and the thicker head allows for a larger hole in the attached panels.

Slide these heavy duty pins into the through hole in a clevis pin then hit them with a hammer to wedge the prongs open.