The air change rate method of calculation is commonly used in cleanrooms with lower cleanliness requirements usually iso 6 to 9 with the air change rate largely based on the level of particles generated by people and processes.

Clean room hvac design calculations.

If you want help with the design of your cleanroom fill out a request for quote and one of our experts will contact you.

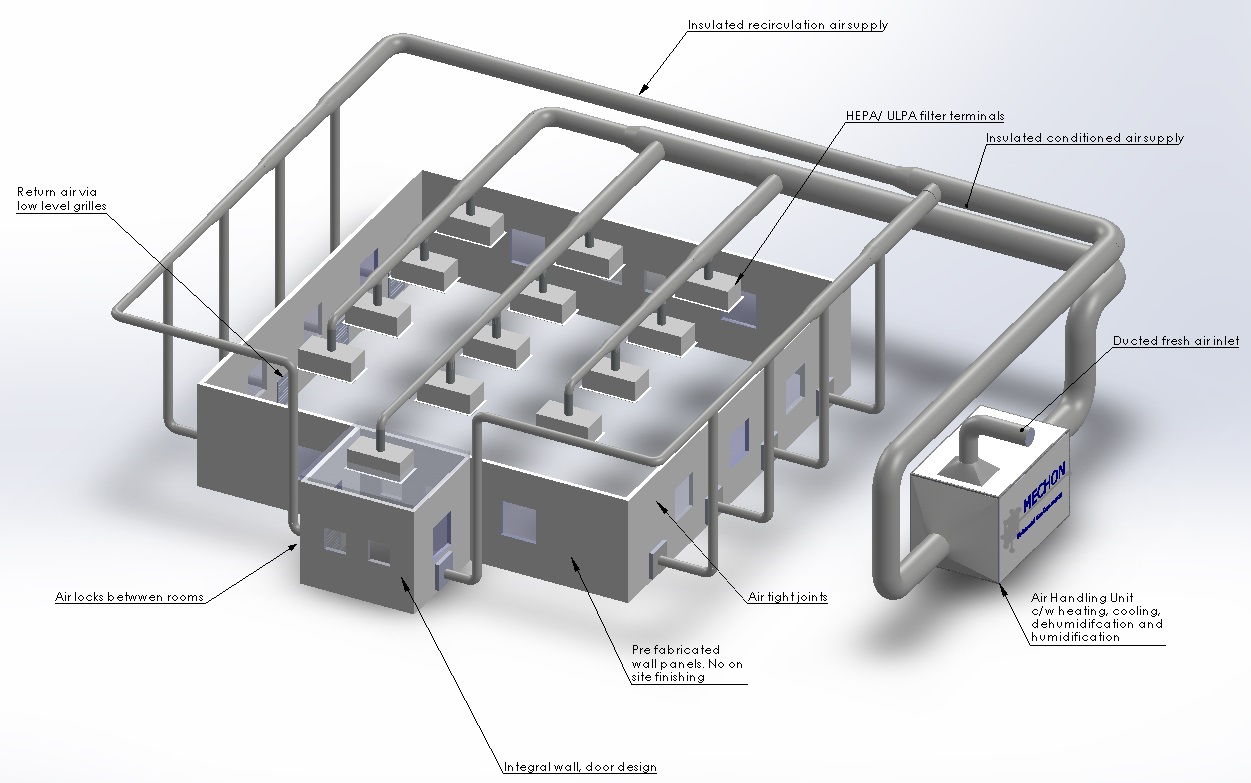

This is achieved by supplying more air to the room than is extracted from it.

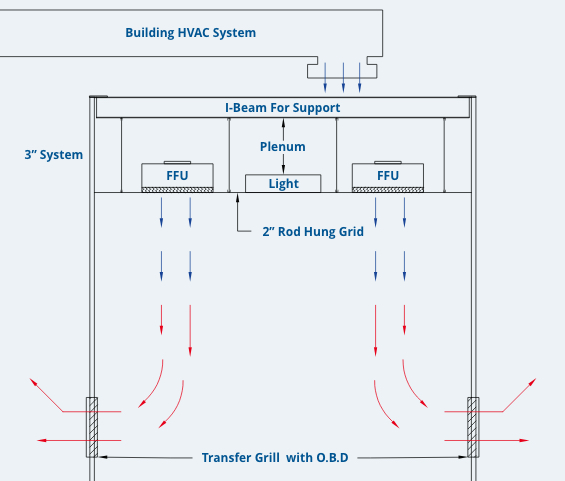

Supplying airflow in sufficient volume and cleanliness to support the cleanliness rating of the room.

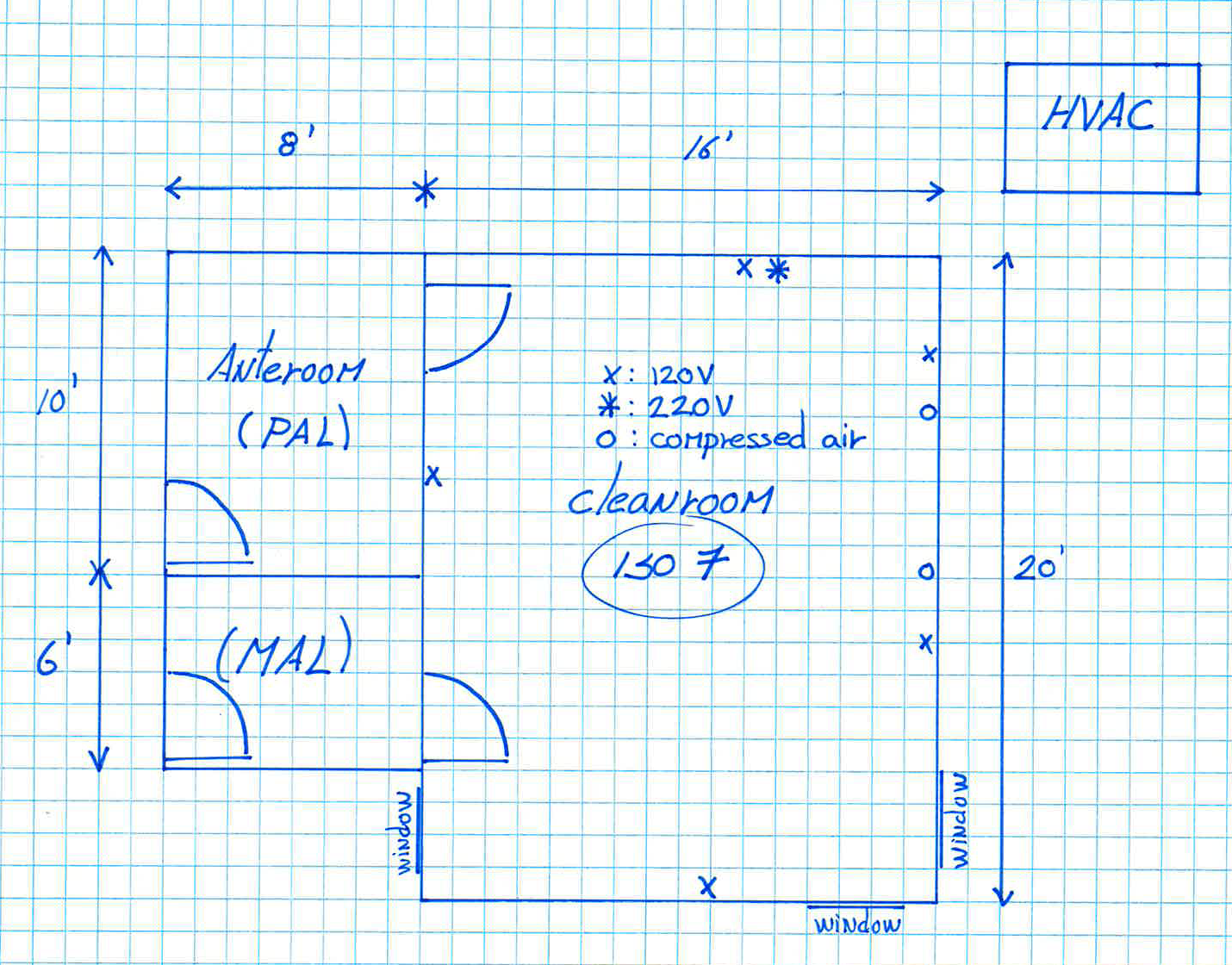

The volume of air in the cleanroom will influence the amount of airflow needed.

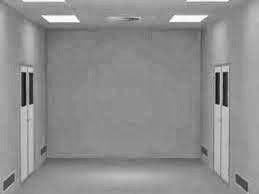

2 the hvac system the integrity of the cleanroom environment is created by the pressure differential compared with adjacent areas through heating ventilation and air conditioning system.

The hvac system requirements include.

Learning points include standards and classifications p.

The bigger the room the more air you need.

People often forget that the height of the room directly impacts the airflow.

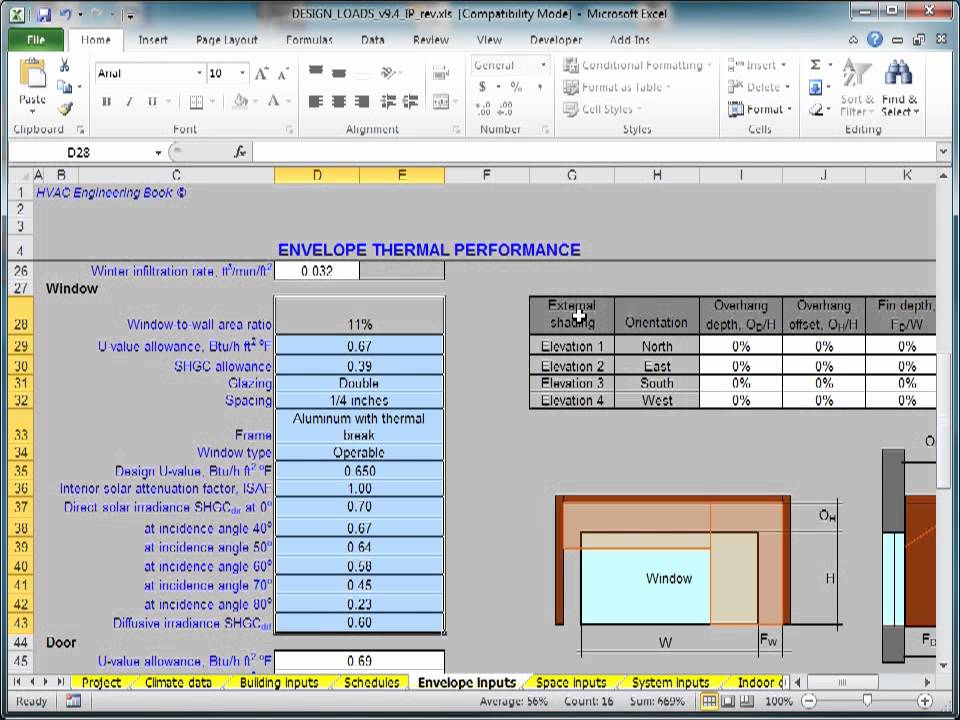

Calculations should be computed by a cleanroom hvac specialist.

During this technical presentation ashrae fellow and distinguished lecturer wei sun discusses the following.

A lot of aspects are not taken into consideration for the calculation including but not limited to heat gain number of people the use of a fume hood etc.